This guide explains requirements in the ABA Standards for floor and ground surfaces. Specifications for floor and ground surfaces address surface characteristics, carpeting, openings, and changes in level. They apply to:

- interior and exterior accessible routes, including walking surfaces, ramps, elevators, and lifts

- stairways that are part of a means of egress

- required clearances, including clear floor space, wheelchair seating spaces, turning space, and door maneuvering clearances

- accessible parking spaces, access aisles, and accessible passenger loading zones.

Firmness, Stability, and Slip Resistance

[§302.1]

Accessible floor and ground surfaces must be stable, firm, and slip resistant. Stable surfaces resist movement, while firm surfaces resist deformation by applied forces. Accessible surfaces remain unchanged by external forces, objects, or materials.

Slip Resistance

Accessible surfaces must be slip resistant to minimize hazards to people with disabilities, especially those who are ambulatory or semi-ambulatory or who use canes, crutches, and other walking aids. However, the standards do not specify a minimum level of slip resistance (coefficient of friction) because a consensus method for rating slip resistance remains elusive. While different measurement devices and protocols have been developed over the years for use in the laboratory or the field, a widely accepted method has not emerged. Since rating systems are unique to the test method, specific levels of slip resistance can only be meaningfully specified according to a particular measurement protocol. Some flooring products are labeled with a slip resistance rating based on a laboratory test procedure.

Compliance with the standards requires specifying surface materials, textures, or finishes that prevent or minimize slipperiness under the conditions likely to be found on the surface. Standard practices for minimizing floor or ground slipperiness will likely satisfy compliance with the standards as slip resistance is important not just for accessibility but for general safety as well. Applications and finishes used to increase a surface material’s slip resistance may require continued maintenance or re-application.

Surface Smoothness

The standards limit changes in level and openings in floor and ground surfaces, but they do not further address overall surface smoothness. Rough surfaces composed of cobblestones, Belgian blocks, and similar materials can be difficult and sometimes painful to negotiate with wheeled mobility aids due to the vibrations they cause.

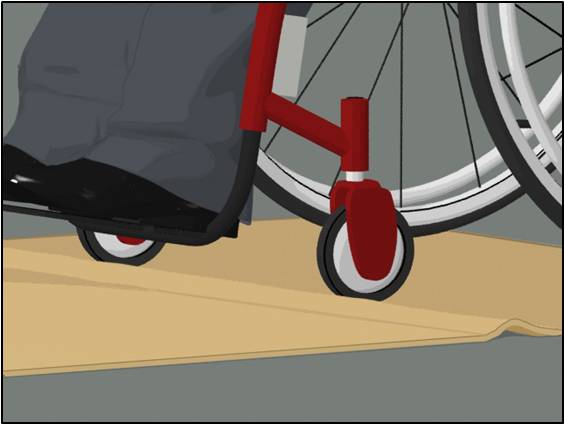

Carpet

[§302.2]

Carpet that is thick, cushiony, or loose impairs accessibility, particularly wheelchair maneuvering. The standards specify the maximum pile height (1/2” measured to the backing, cushion, or pad) and texture (level or textured loop, level cut pile, or level cut/uncut pile) and require firm backing. Cushions or pads also must be firm or can be avoided to ensure greater firmness.

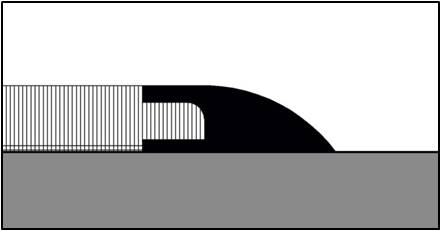

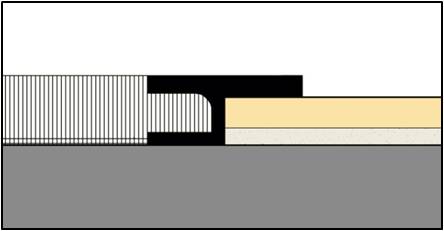

Exposed edges must have trim on the entire length of the exposed edge and be fastened to the floor to prevent curling. Trim must meet specifications for changes in level, including requirements for beveled edges when the height exceeds ¼ inch. The maximum height is ½ inch.

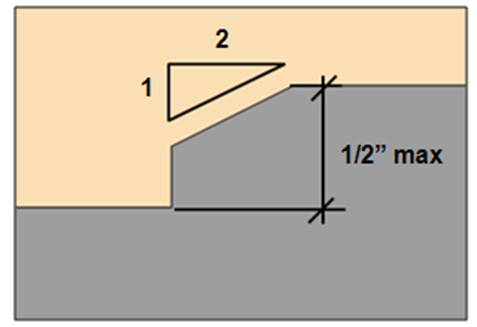

1/2” max height, 1:2 max beveled edge

1/2” max height, 1:2 max beveled edge

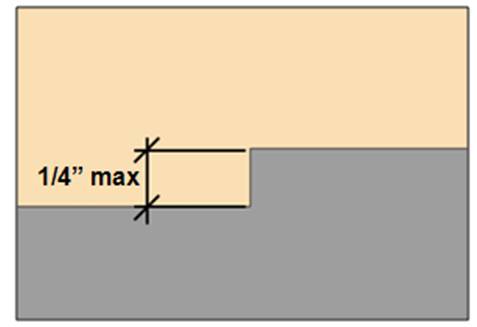

Changes in level 1/4” max high permitted vertical edge

Changes in level 1/4” max high permitted vertical edge

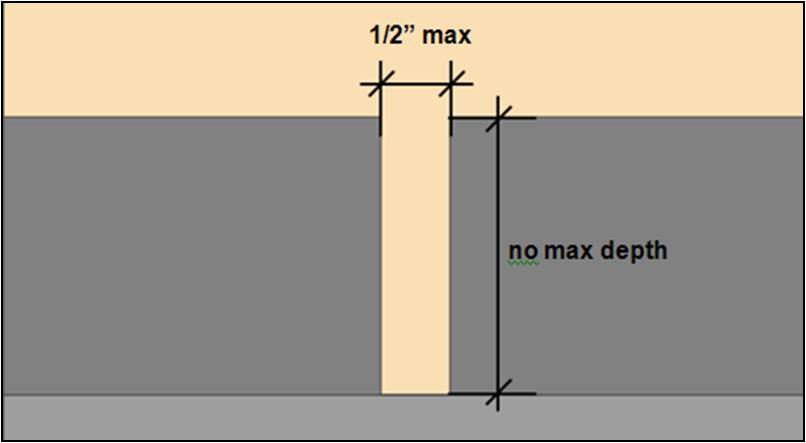

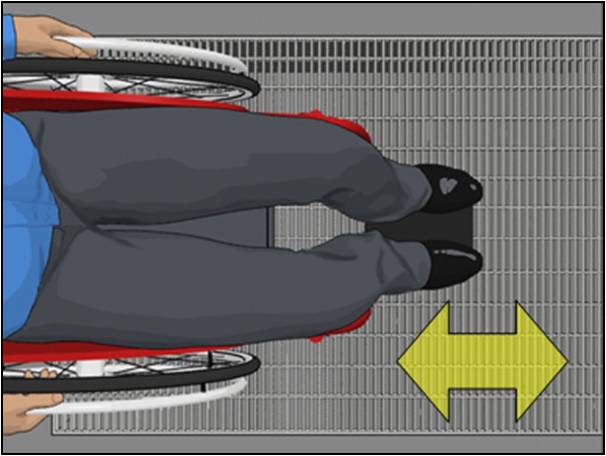

Openings

[§302.3]

Openings in ground and floor surfaces, such as grates, are limited in width to prevent passage of a ½” diameter sphere. Wheelchair casters can get wedged into wider openings.

Surface Opening (Cross Section)

Changes in Level

[§303

Changes in level can be up to ¼” without treatment or ½” if beveled with a slope no steeper than 1:2. Changes in level above a ½” must be treated as a ramp or curb ramp (or a walkway if a slope no steeper than 1:20 can be achieved). These specifications apply to all portions of accessible routes, including thresholds and carpet trim.

Common Questions

Must accessible surfaces be paved?

Concrete, asphalt, and other paved surfaces are more reliably compliant, but other materials, such as wood, and construction methods can be used to provide firm and stable surfaces. Loose material like gravel will not perform adequately unless it is sufficiently stabilized by binders, compaction, or other treatments and will likely require repeated maintenance.

What is the minimum level of slip resistance required by the standards?

The standards require ground and floor surfaces to be slip resistant, but they do not specify a minimum level of slip resistance or coefficient of friction. This value varies according to the measurement method and protocols used. Some products are labeled with a rated level, but in the absence of a consensus test procedure, the standards do not set a minimum value. Standard methods to prevent or minimize slipperiness in the specification of floor materials, textures, applications, and finishes may be sufficient for compliance with the standards.

Is there a minimum distance between changes in level?

The standards do not require a minimum horizontal separation between changes in level of a ½” or less. Such level changes may need to be in close proximity, such as at raised thresholds (otherwise a minimum 48” separation will provide enough wheelchair space so that only one vertical change is negotiated at a time). Ramps and curb ramps, which must be used to span vertical changes greater than ½”, must have level landings and clearances at the tops and bottoms of each run to provide adequate separation and resting intervals between sloping surfaces.

Elongated surface openings must be perpendicular to the dominant direction of travel, but what if there is no dominant direction of travel?

When there is no dominant direction of cross traffic, openings must be limited to ½” in both dimensions. Where space allows accessible routes to completely bypass the area with openings, elongated openings can be oriented in either direction.